In today’s fast-paced world of automation, industrial and electronic systems demand uninterrupted performance and stability. Yet, as devices become more powerful and compact, electromagnetic interference (EMI) has become one of the biggest challenges.

That’s where the Choke Inductor Coil steps in. Acting as a silent guardian, it filters electrical noise, protects circuits, and ensures the smooth operation of sensitive equipment. In this article, we’ll explore why choke inductor coils are essential for reducing EMI in industrial systems — and how ZYCOIL provides innovative solutions for global manufacturers.

⚙️ Understanding the Basics of Choke Inductor Coils

What Is a Choke Inductor Coil?

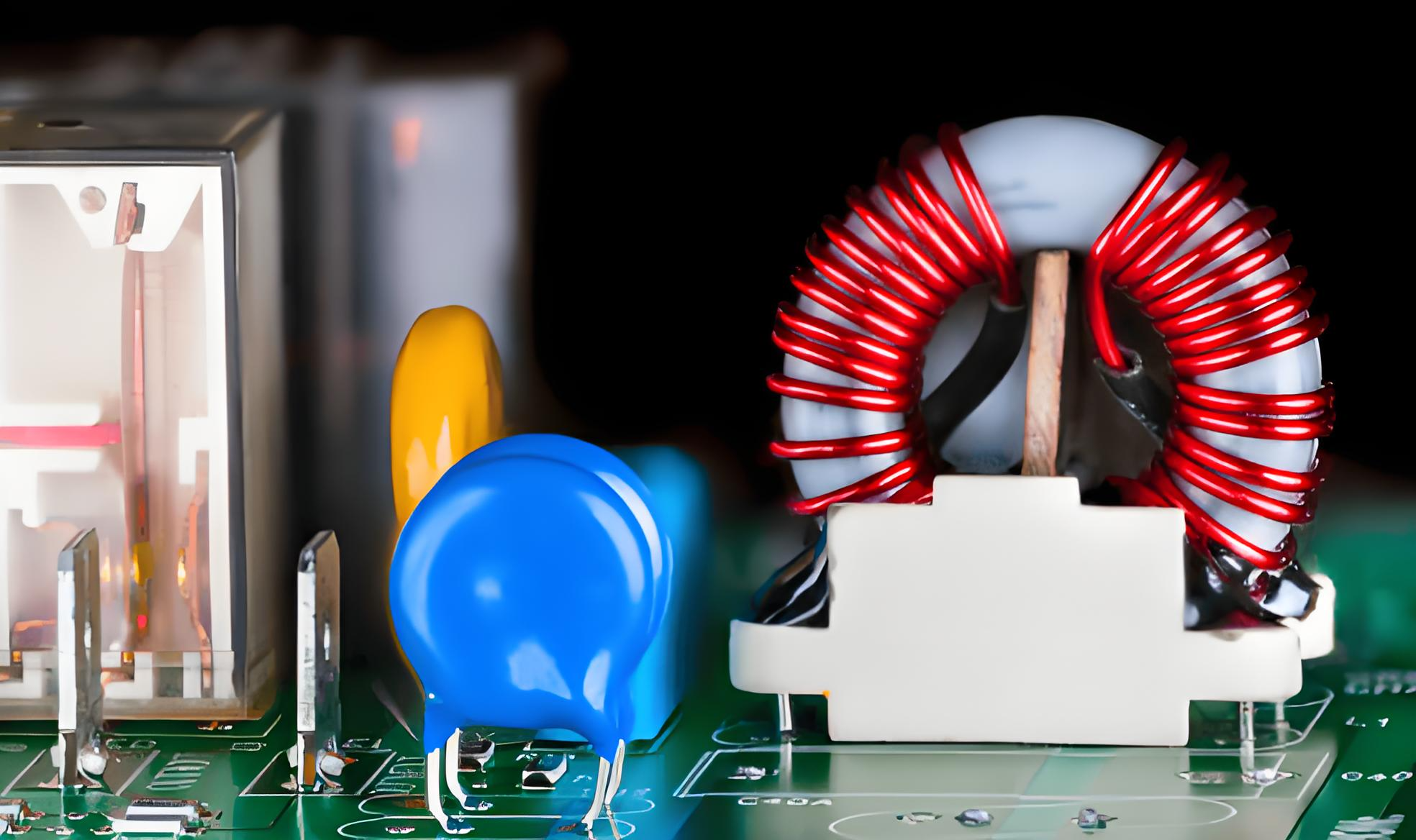

A Choke Inductor Coil is a passive electronic component designed to block or “choke” high-frequency noise while allowing DC or low-frequency AC currents to pass. It plays a vital role in EMI suppression and power line filtering.

In industrial settings, EMI can come from switching power supplies, electric motors, or digital communication signals. Without proper filtering, it can disrupt machine operation, cause data loss, or even damage components.

Key functions of a choke inductor coil include:

-

Suppressing high-frequency electrical noise

-

Improving signal stability and power quality

-

Protecting circuits from voltage fluctuations

-

Enhancing electromagnetic compatibility (EMC)

🏭 The Role of Choke Inductor Coils in Industrial Systems

1. EMI Suppression and Signal Purity

Every industrial system involves numerous power and control lines. These lines can become sources of interference. A Choke Inductor Coil reduces unwanted noise by resisting changes in current, allowing only clean signals to pass through.

For example:

-

In motor drives, it prevents noise from reflecting back into the power line.

-

In PLC systems, it stabilizes communication signals for consistent data flow.

-

In automation sensors, it shields circuits from electromagnetic coupling.

2. Protecting Power Electronics and Components

Industrial power systems operate under high loads. Switching converters, inverters, and variable frequency drives (VFDs) often generate high-frequency ripples. These can shorten the lifespan of capacitors or cause component overheating.

By integrating a power filter inductor, engineers can limit current spikes, reduce EMI, and protect expensive equipment.

ZYCOIL’s industrial choke coils are engineered for durability and performance — maintaining inductance stability under thermal and electrical stress.

3. Enhancing Energy Efficiency

While the primary goal of a choke inductor coil is EMI suppression, it also contributes to energy efficiency. By reducing unwanted current fluctuations and harmonics, it minimizes wasted energy in circuits.

This results in:

-

Lower heat generation

-

Reduced power losses

-

Increased overall system efficiency

For industries focusing on sustainable manufacturing, such energy savings directly support green production goals.

🔋 Types of Choke Inductor Coils and Their Applications

1. Common Mode Choke Coils

Common mode chokes filter out common-mode noise — signals that appear identically on both lines of a power circuit.

Applications: Power supplies, converters, industrial automation, and communication systems.

2. Differential Mode Choke Coils

These are designed to suppress differential noise, which occurs between two signal lines.

Applications: High-speed data transmission, control modules, and precision instrumentation.

3. Toroidal Choke Inductors

Toroidal coils use a ring-shaped core, which minimizes magnetic leakage and improves efficiency.

Applications: Medical electronics, power conditioning units, and inverter circuits.

4. Air Core Choke Coils

These coils are free of magnetic materials, ideal for high-frequency RF and communication systems.

Applications: Antenna circuits, RF amplifiers, and telemetry systems.

🌐 Industries That Rely on Choke Inductor Coils

Industrial Automation

Choke inductors protect sensors, drives, and controllers from noise that can cause system errors or production downtime.

Automotive & New Energy

Used in EV charging systems and battery management, choke inductors help reduce EMI in high-voltage environments.

Communication & RF Systems

High-frequency choke coils stabilize signals in 5G base stations, routers, and radar equipment.

Medical & Precision Instruments

They ensure the reliability of diagnostic tools by filtering unwanted interference in sensitive measurement circuits.

Power & Renewable Energy

In solar inverters and energy converters, choke inductors regulate power flow, improving reliability and extending lifespan.

🧠 How ZYCOIL Ensures Superior EMI Performance

At ZYCOIL, we combine advanced materials and precise winding techniques to ensure every Choke Inductor Coil delivers optimal EMI suppression.

Our key advantages:

-

USTC-certified materials ensuring consistent performance

-

High-current and low-loss designs for industrial environments

-

Custom solutions for automotive, medical, and communication sectors

-

Rigorous testing for temperature endurance, inductance stability, and reliability

Whether for OEM production or specialized system integration, ZYCOIL ensures every coil meets global EMI compliance standards.

💡 Why EMI Reduction Is Critical for Modern Manufacturing

With the rise of Industry 4.0, smart factories depend on seamless communication and data flow. EMI interference can cause signal errors, disrupt automation, and even lead to costly production halts.

By using reliable choke inductor coils, manufacturers can:

-

Maintain equipment accuracy

-

Comply with international EMC standards

-

Protect investments in automation technology

Simply put, EMI control isn’t optional—it’s essential for safe and efficient manufacturing.

🔧 Choosing ZYCOIL as Your Choke Inductor Coil Partner

ZYCOIL provides tailor-made choke coil solutions for every application—from low-frequency industrial filters to high-frequency RF designs.

Why choose us:

-

Decades of experience in CNC winding and coil technology

-

Custom inductance range from microhenries to millihenries

-

Fast prototyping and OEM support

-

Global supply capability with stable lead times

When precision and reliability matter, choose ZYCOIL — your trusted partner for EMI control and coil innovation.

🧭 Conclusion

Choke Inductor Coils are the foundation of effective EMI control in industrial systems. From energy efficiency to equipment safety, their role is indispensable across all modern industries.

With the right materials, precision design, and testing, ZYCOIL delivers coils that ensure stable power, accurate signals, and long-term performance.

In a world powered by electronics, reducing EMI means protecting progress — and ZYCOIL is leading the way.

❓FAQs About Choke Inductor Coils

1. What causes EMI in industrial systems?

EMI often results from switching power supplies, motors, and high-frequency circuits that generate electrical noise.

2. How does a choke inductor coil reduce EMI?

It resists sudden changes in current, filtering high-frequency noise while allowing the main signal to pass.

3. Can choke coils improve energy efficiency?

Yes. By stabilizing current flow and minimizing power loss, choke inductors help enhance overall system efficiency.

Leave A Comment