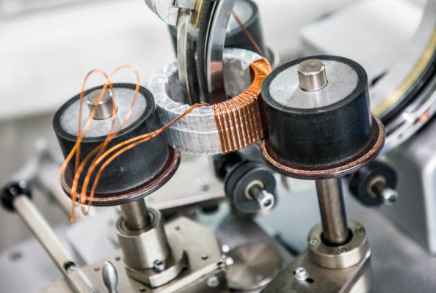

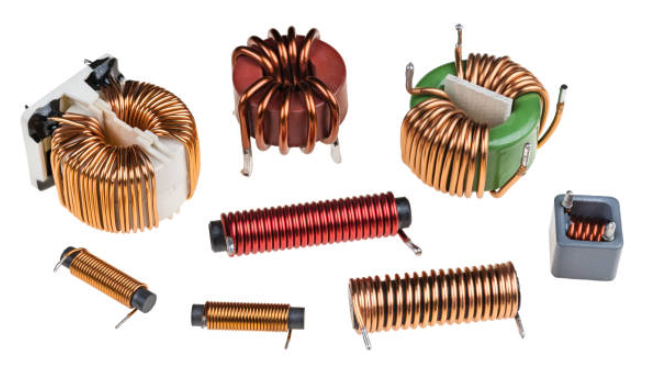

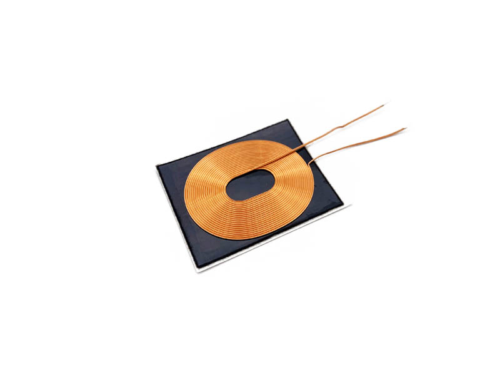

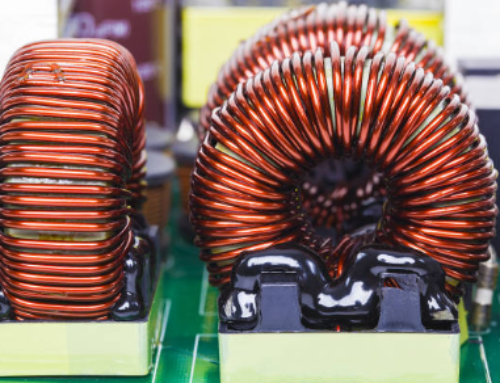

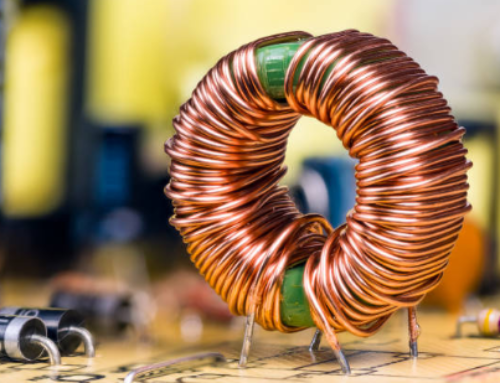

Whether you’re in electronics manufacturing, industrial applications, or consumer electronics, wire wound inductor coils are fundamental components that ensure the stability and performance of circuits and power supplies. These coils are used to store energy, filter signals, and manage power in a wide variety of applications.

For businesses looking to source wire wound inductor coil wholesale, finding the right supplier is crucial. High-quality inductors can enhance the efficiency and reliability of your products, while poor-quality coils can lead to system failures, inefficiency, and increased costs.

Key Factors to Consider When Sourcing Wire Wound Inductor Coil Wholesale

1. Material Quality and Performance

The material used in the winding of the inductor coil significantly impacts its performance and longevity. The most commonly used materials are copper and aluminum for their excellent conductivity. However, certain applications may require specialized alloys or coatings to enhance performance.

-

Copper wire is ideal for general-purpose inductors due to its superior conductivity and cost-effectiveness.

-

Aluminum wire is preferred for high-frequency and lightweight applications.

-

Special alloys may be used for specific performance requirements, such as reduced eddy current losses or better temperature tolerance.

Tip: When sourcing wire wound inductor coil wholesale, ensure the material aligns with your project’s specifications. Higher-quality materials can lead to better overall performance, especially in demanding applications like high-frequency circuits and power systems.

2. Electrical Specifications and Performance Metrics

Before placing an order for wire wound inductor coils, it’s essential to understand the electrical requirements for your project. Key specifications to consider include:

-

Inductance: The coil’s ability to store energy in a magnetic field.

-

Saturation Current: The current at which the inductor’s inductance begins to drop significantly.

-

DC Resistance (DCR): The resistance of the wire, which affects the efficiency of the coil.

-

Q Factor: The quality factor, which measures the efficiency of the coil in energy storage.

Tip: Always ensure that the inductance, current rating, and resistance specifications match your project’s needs. Working with a supplier who can provide detailed performance data will help you avoid problems like overheating or signal distortion in your circuits.

3. Customization Capabilities for Your Application

For businesses engaged in custom projects, customization of wire wound inductor coils may be necessary. Many suppliers offer the ability to modify the coil size, shape, and material properties to suit specific requirements. Some key customizations include:

-

Shape and size: Coils can be designed to fit specific circuit designs or available space.

-

Coating options: Certain projects require additional coatings for protection against moisture, heat, or corrosion.

-

Inductance tolerance: Customized tolerance levels can ensure that your coil performs precisely as required.

Tip: Work with suppliers who can provide flexible customization options. This allows you to meet the exact specifications of your custom project and optimize performance.

4. Supplier Reputation and Quality Assurance

When sourcing wire wound inductor coil wholesale, choosing a reputable supplier is crucial. The supplier’s ability to meet quality standards and provide reliable, high-performance coils will directly impact the success of your projects.

Ensure that your supplier has:

-

Certifications: Look for suppliers with ISO certifications or similar industry standards.

-

Testing and quality control: Ask for testing reports and data to verify that the coils meet the required specifications.

-

Track record: A supplier with a history of successful projects in your industry will offer confidence in the quality and reliability of their coils.

Tip: Always request product samples and conduct tests before committing to a large order. This ensures that the coils meet your specifications and quality standards.

5. Cost-Effectiveness and Lead Time

Cost is always an important factor in wholesale sourcing, but it should not come at the expense of quality. While wire wound inductor coils can vary in price depending on material and customization, it’s essential to evaluate the overall value of the coils.

Consider the following when sourcing wholesale:

-

Volume discounts: Many suppliers offer lower prices per unit for large orders.

-

Shipping costs: Account for the total cost, including shipping and customs if you’re sourcing internationally.

-

Lead time: The ability of a supplier to meet delivery deadlines is critical, especially for large-scale or time-sensitive projects.

Tip: Request detailed pricing quotes and production timelines. Compare these factors across multiple suppliers to find the best combination of price, quality, and delivery speed.

Why Choose ZYCOIL for Your Wire Wound Inductor Coils?

At ZYCOIL, we specialize in providing high-quality wire wound inductor coil wholesale for a wide range of applications. With a focus on precision manufacturing and stringent quality control, our coils are designed to meet the unique needs of industries like consumer electronics, industrial power systems, and telecommunications.

We offer:

-

Custom coil designs: Tailored to your exact specifications, including size, shape, and material.

-

Reliable quality assurance: All of our coils undergo rigorous testing to ensure they meet performance and durability standards.

-

Competitive pricing: We offer bulk pricing discounts to help you save on large orders without compromising quality.

Choose ZYCOIL for your wire wound inductor coil wholesale needs and ensure your projects succeed with reliable, high-performance coils.

Conclusion:

Sourcing wire wound inductor coil wholesale is a critical step in ensuring the success of your custom projects. By considering factors like material quality, electrical specifications, supplier reputation, and cost-effectiveness, you can make informed decisions that will enhance the performance of your products.

At ZYCOIL, we provide top-tier inductor coils designed to meet the demanding requirements of your business. Whether you need standard or custom coils, our team is here to support your needs and help you succeed in your industry.

FAQ:

1. What materials are typically used for wire wound inductor coils?

Copper and aluminum are the most common materials, but special alloys can be used for high-frequency or high-temperature applications.

2. How do I ensure the quality of wire wound inductor coils?

Choose a supplier with strong quality assurance practices, certifications, and testing protocols. Always request samples before committing to bulk orders.

3. What customization options are available for wire wound inductor coils?

Customization options include size, shape, material, coating, and inductance tolerance. Discuss your project’s needs with the supplier to ensure they can meet your specifications.

Leave A Comment