In modern RF (Radio Frequency) applications, signal integrity determines overall system performance. From wireless communication to automotive radar and medical imaging, even minor signal loss can lead to inefficiency and data errors. This is where air core coils come in — offering low-loss performance, high-frequency stability, and clean signal transmission.

For industrial manufacturers, RF engineers, and B2B suppliers, understanding how Wholesale Custom Air Core Coil minimize signal loss is key to achieving both reliability and cost efficiency. Let’s explore why these coils are crucial for next-generation electronic systems — and why choosing ZYCOIL can make a difference.

What Makes Air Core Coils Unique in RF Design?

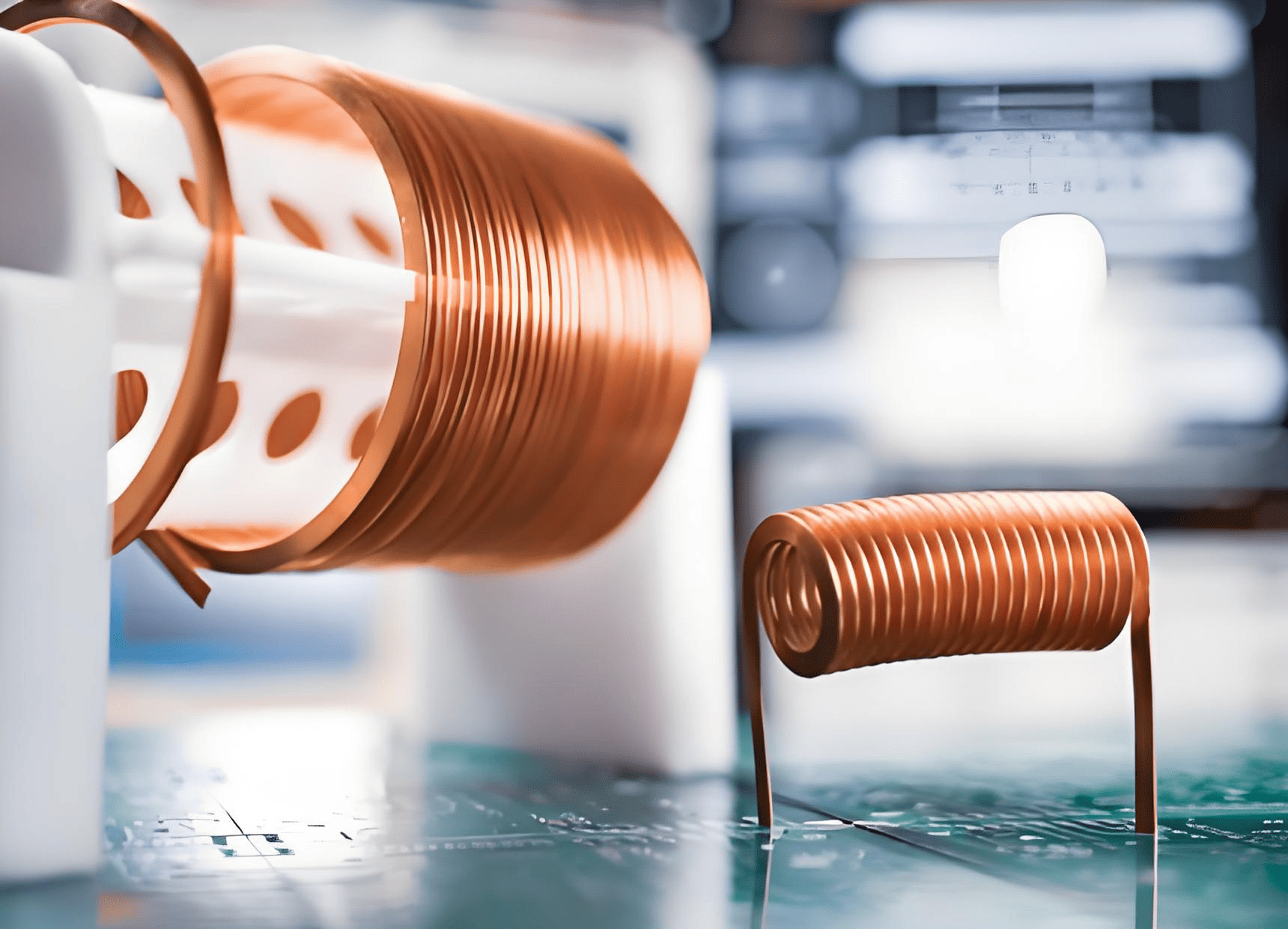

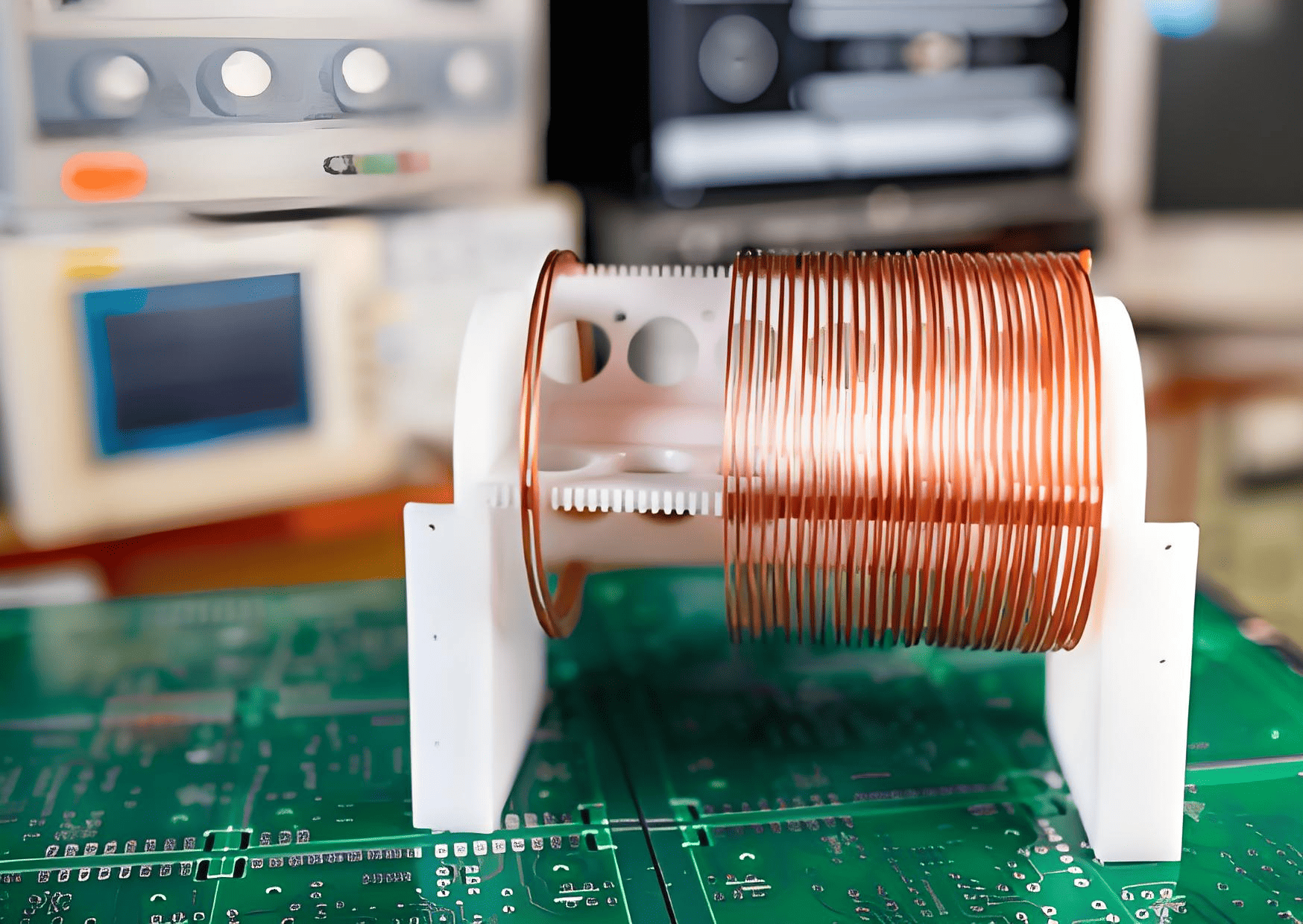

Unlike ferrite or iron-core inductors, air core coils use air as the magnetic medium. This eliminates core losses and magnetic distortion, providing stable inductance across wide frequencies.

Key Characteristics of Air Core Coils

-

No Magnetic Saturation – Air cores avoid nonlinear distortion caused by magnetic materials.

-

Low Hysteresis and Eddy Losses – Ideal for high-frequency RF applications requiring clean signals.

-

High Q-Factor – Ensures better energy efficiency and reduced resistive losses.

-

Customizability – Wholesale Custom Air Core Coil can be wound for specific frequencies, inductance, or impedance requirements.

These properties make air core coils the preferred choice for RF amplifiers, transmitters, antennas, and filters, where precise signal control is essential.

How Air Core Coils Reduce Signal Loss

Signal loss in RF systems often results from resistance, dielectric absorption, or magnetic saturation. Air core coils minimize these effects through design efficiency and superior materials.

1. Low Core Loss for High-Frequency Operation

Since air doesn’t introduce core loss, these coils maintain consistent performance across a broad frequency range — from MHz to GHz. This is vital for communication devices, radar systems, and RF power amplifiers.

2. Reduced Eddy Current and Heat Buildup

In metal-core inductors, eddy currents can cause unwanted heat and energy loss. Air core designs naturally eliminate this issue, ensuring thermal stability and longer component life.

3. Improved Q-Factor and Energy Transfer

A higher Q-factor means less resistive energy loss. Air core coils maintain high Q values, allowing cleaner signal transmission with reduced attenuation — critical for data accuracy in RF circuits.

4. Optimized Coil Geometry

With precise winding geometry, custom air core coils from ZYCOIL can be optimized for minimal parasitic capacitance and inductive coupling — ensuring greater signal clarity even under complex load conditions.

Applications Across Industries

Air core coils aren’t limited to one industry — they power diverse high-frequency systems across multiple sectors.

1. Communication & RF Engineering

-

Used in antennas, filters, and tuners

-

Enhance transmission efficiency and reduce interference

2. Automotive Electronics & EV Systems

-

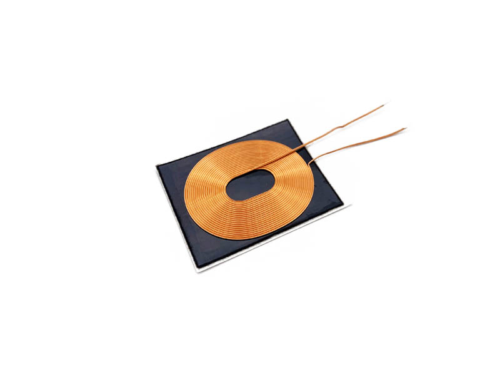

Ideal for radar, sensor modules, and wireless chargers

-

Offer stable operation in varying temperature environments

3. Medical Equipment

-

Support imaging systems and diagnostic devices

-

Deliver consistent frequency response with minimal EMI

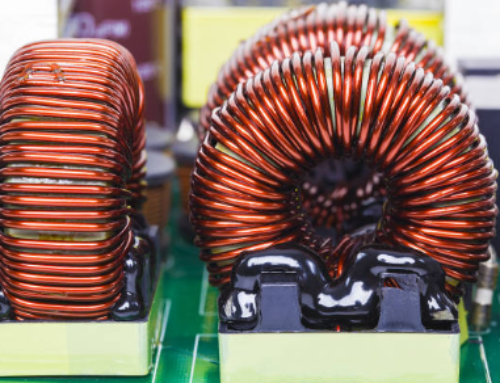

4. Power & Energy Conversion

-

Applied in inverter and converter circuits

-

Maintain low distortion for precise signal control

Choosing wholesale custom air core coil ensures both cost-effective scaling and consistent component quality — a major advantage for OEM and international distributors.

Why Choose ZYCOIL for Wholesale Custom Air Core Coil?

When performance and reliability matter, partnering with an experienced manufacturer is crucial. ZYCOIL specializes in designing and producing customized air core inductors for demanding RF and industrial environments.

Our Advantages:

-

✅ Precision Engineering – Every coil is manufactured under ISO and RoHS-compliant standards.

-

✅ Wide Customization Range – Tailor inductance, wire gauge, or coil diameter for your system.

-

✅ High Consistency for B2B Supply – Bulk production ensures stable quality and cost control.

-

✅ Technical Support – Expert engineers assist in prototype design and EMI reduction strategies.

By working with ZYCOIL, OEM and B2B clients gain a trusted partner capable of balancing innovation with scalability — ensuring every air core coil delivers optimal RF performance.

Conclusion: The Future of Low-Loss RF Design

As industries move toward faster, cleaner, and smarter communication systems, minimizing signal loss becomes a top priority. Wholesale Air Core Coils offer the perfect solution — combining high-frequency performance with customization flexibility.

Whether you’re developing RF modules, power converters, or advanced automotive electronics, choosing ZYCOIL means choosing reliability, precision, and sustainability.

FAQs About Air Core Coils in RF Applications

1. Why are air core coils better for high-frequency circuits?

Because they have no magnetic core, air core coils minimize core losses and distortion, maintaining stable inductance across high frequencies.

2. Can air core coils handle high power levels?

Yes. With proper design and wire selection, they can support high current and power levels while avoiding heat buildup.

3. Does ZYCOIL offer custom air core coil designs for OEM projects?

Absolutely. ZYCOIL provides full customization — from inductance range to coil shape — ensuring your design meets precise RF and EMI performance standards.

Leave A Comment