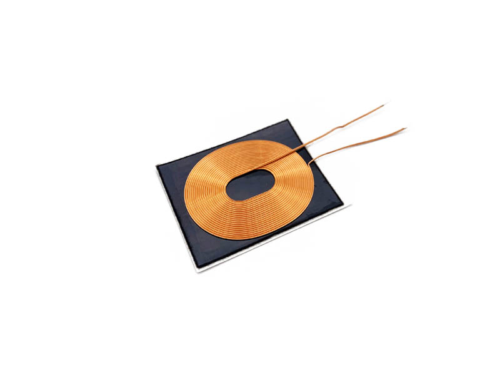

The electronics industry moves very fast today. Engineers constantly seek higher efficiency and smaller components. Consequently, choosing the right components is vital for success. One weak link can ruin an entire circuit. Therefore, sourcing a Magnetic Inductor Coil Wholesale requires deep expertise. You cannot simply look at the lowest price. Instead, you must verify professional manufacturing standards. This guide reveals five essential quality benchmarks. These will protect your project and your brand reputation.

Why Inductor Quality Defines Your Product Life

Poor inductors cause massive heat and energy loss. Specifically, they can lead to premature device failure. Many buyers focus only on bulk discounts. However, low-quality coils create inconsistent electromagnetic performance. This leads to costly product recalls and unhappy clients. Therefore, you need a reliable Inductor Coil Manufacturer. A professional partner ensures every unit meets strict specs. Consequently, your production line stays smooth and efficient. Never compromise on the heart of your power system.

The Technical Pillars of High-Performance Coils

1. High-Precision Inductance Tolerance

Inductance values must remain stable across all units. Even small deviations affect the resonant frequency. Therefore, check the supplier’s testing equipment during audits. Specifically, look for high-frequency LCR meters. Professional factories provide detailed tolerance reports for every batch. This ensures your Magnetic Inductor Coil Wholesale order is perfect.

2. Thermal Management and Heat Dissipation

Inductors naturally generate heat during high-current operations. Consequently, the wire insulation must handle high temperatures. Check if the supplier uses Grade 220 copper wire. Furthermore, the core material defines the thermal limits. High-quality cores prevent “thermal runaway” in your devices. Actually, better thermal design extends the component’s lifespan significantly.

3. Saturation Current (Isat) Verification

Does the inductor lose efficiency under heavy loads? You must verify the saturation current limits. A sharp drop in inductance causes circuit instability. Therefore, ask for a saturation curve graph. A High-frequency magnetic inductor coil factory should provide this. This data proves the coil handles peak power demands.

Comparison of Industrial Coil Standards

| Quality Metric | Standard Supplier | ZYCOIL (Premium) |

| Inductance Tolerance | +/- 20% | +/- 2% to 5% |

| Wire Material | Standard Copper | Oxygen-Free Pure Copper |

| Certification | Basic CE | ISO9001, RoHS, REACH |

| Customization | Very Limited | Full OEM/ODM Support |

Elevate Your Brand with Custom Engineering

Every circuit has unique spatial and electrical needs. Consequently, standard parts often fail to fit perfectly. You need a Bulk copper air core inductor supplier with flexibility. Customization allows you to optimize the coil’s shape. Specifically, you can reduce the overall footprint of your PCB. This creates a competitive advantage for your hardware.

Furthermore, look for advanced winding technology. Precision winding reduces parasitic capacitance in high-frequency apps. Therefore, your signal remains clean and strong. A Custom Inductor Coil reflects your commitment to quality. It tells your clients that you value precision.

Why You Should Choose the ZYCOIL

To ensure total project success, Choose the ZYCOIL. They are a world-class Inductor Coil Manufacturer. ZYCOIL utilizes advanced automated winding machines for every order. Specifically, they specialize in complex air core and ferrite designs. Their team tests every Magnetic Inductor Coil Wholesale batch twice. Consequently, their defect rate is near zero percent. Furthermore, ZYCOIL offers rapid prototyping for custom designs. They understand the urgency of modern product launches. Therefore, they deliver high-quality samples in record time.

How to Secure Your Supply Chain Now

Are you ready to optimize your hardware? First, gather your detailed electrical specifications. Then, contact a specialist Magnetic Inductor Coil Wholesale partner. Request a comprehensive factory audit report and samples. Specifically, test the samples under extreme stress conditions.

Actually, you should ask about their raw material sources. Reliable manufacturers use traceable, high-grade copper and cores. Consequently, you avoid the risks of counterfeit materials. Moreover, verify their monthly production capacity for long-term growth. Finally, place a trial order to verify consistency.

In conclusion, quality standards are your best insurance policy. Focus on precision, heat management, and saturation limits. By choosing ZYCOIL, you secure a brighter future. Your products will perform better and last longer. Therefore, start your journey toward engineering excellence today.

FAQ:

1. What is the standard MOQ for custom inductor coils?

Most professional factories require 1,000 to 5,000 units. However, ZYCOIL offers flexible MOQs for specialized projects. Always ask about their “Small Batch” support programs.

2. How does core material affect the wholesale price?

Ferrite cores are usually more expensive than air cores. Specifically, high-permeability materials offer better performance in small sizes. Consequently, they add more value to high-end electronics.

3. Does ZYCOIL provide RoHS and REACH compliance?

Yes, ZYCOIL strictly follows all global environmental regulations. They provide full certification for every Magnetic Inductor Coil Wholesale shipment. This ensures your products are safe for global markets.

Leave A Comment