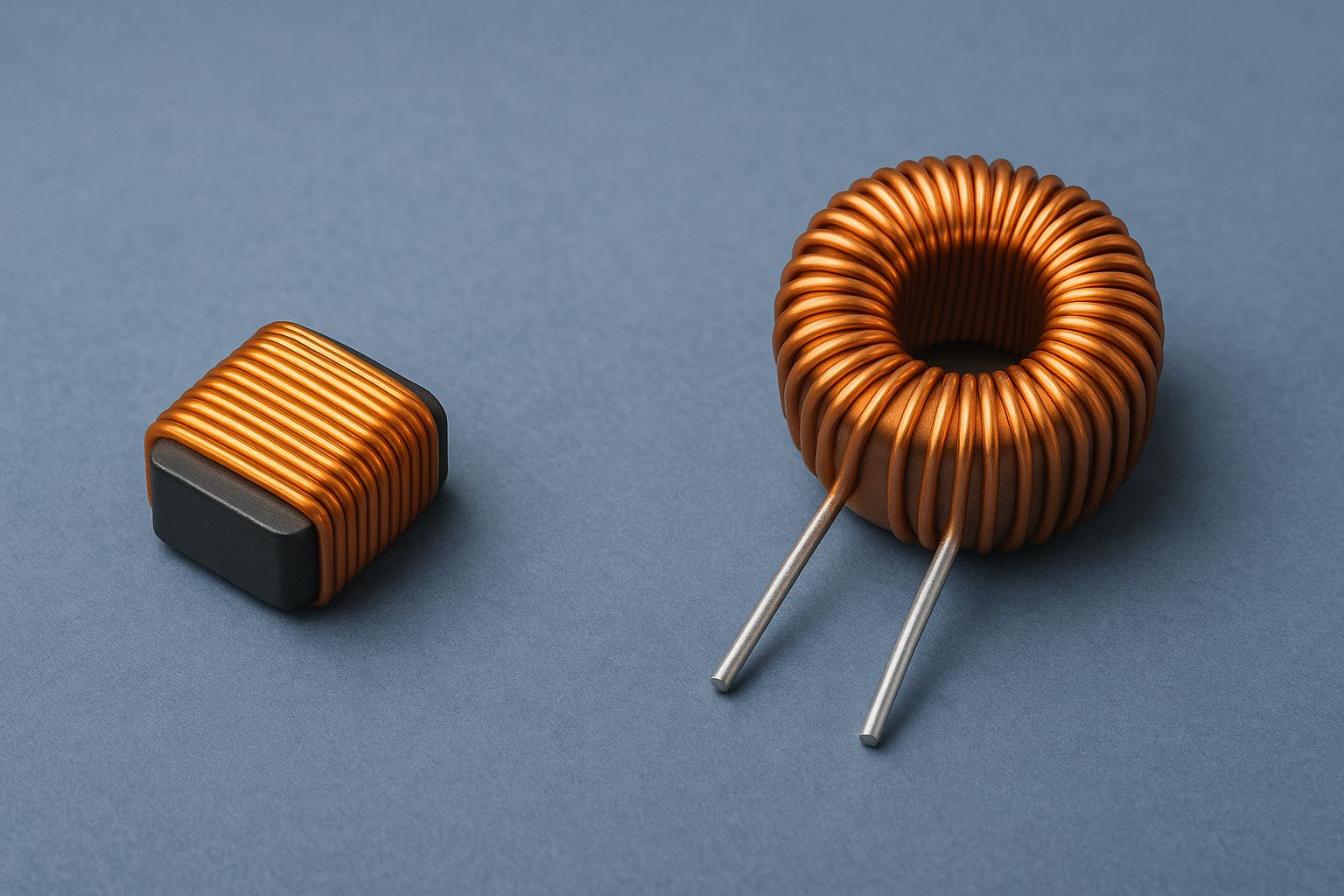

Copper inductor coils are essential in many electronic circuits. Among them, SMD (Surface-Mount Device) and through-hole types are the most widely used. Although both perform similar functions, their structures, installation methods, and applications differ greatly. Therefore, choosing the right one requires understanding these key differences.

Key Structural Differences

SMD inductor coils are compact and sit directly on the PCB surface. They use solder pads for electrical connection. In contrast, through-hole inductors have long leads that go through PCB holes, making mechanical bonding stronger. As a result, SMD coils are better suited for automated assembly. However, through-hole types often offer higher current handling due to their size and robustness.

Application Scenarios

When space is limited and high-density circuit boards are needed, SMD inductors are ideal. For example, smartphones, tablets, and other compact devices benefit from SMD components. Additionally, they reduce parasitic inductance and improve signal performance in high-frequency applications. On the other hand, through-hole copper inductors are often used in power supplies, industrial equipment, and automotive systems. These applications require durability, heat dissipation, and mechanical stability—strengths of through-hole designs.

Performance and Reliability

SMD coils perform excellently in high-frequency circuits due to their low profile and short leads. However, they may not dissipate heat as effectively as through-hole inductors. This makes through-hole types more reliable in high-power conditions.

Nevertheless, SMD coils continue to improve in current capacity. As materials and manufacturing advance, some modern SMD designs now rival through-hole performance.

Manufacturing Considerations

From a production standpoint, SMD inductors support full automation. This reduces labor costs and speeds up assembly. Conversely, through-hole coils often require manual or semi-automated insertion, which slows down production and increases cost. Moreover, using SMD coils allows for double-sided PCB design, saving even more board space. This flexibility is essential in high-efficiency, modern electronics.

How to Choose the Right Type

Choosing between SMD and through-hole copper inductors depends on several factors:

- Current rating: For higher currents, through-hole may be better.

- Size constraints: SMD coils are ideal for compact designs.

- Assembly process: Automated lines favor SMD components.

- Mechanical stress: Through-hole types are more physically secure.

Ultimately, each application has its priorities. Balancing electrical performance, mechanical strength, and production efficiency will lead to the best choice.

Conclusion

In conclusion, both SMD and through-hole copper inductor coils have clear advantages. SMD coils suit compact, high-speed circuits, while through-hole inductors excel in power and durability. Understanding your circuit’s needs helps guide optimal component selection. As electronics evolve, engineers must weigh all design factors to ensure long-term performance and reliability.

Welcome to browse our copper inductor coils

Leave A Comment