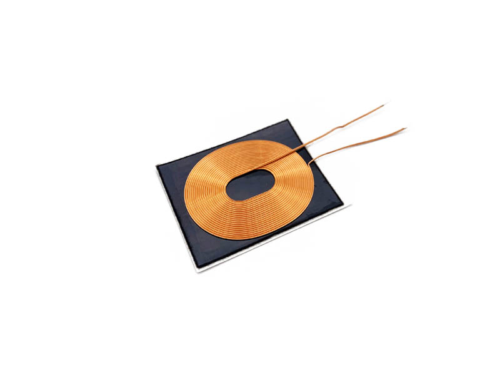

The electronics world moves toward miniaturization today. Engineers face tougher challenges with every new design. Specifically, managing electromagnetic interference (EMI) is very difficult. Traditional drum inductors often fail in compact spaces. Consequently, professional designers seek better technological alternatives. SMD Toroidal Inductor Coils have become the industry standard. They offer superior performance in high-density PCB layouts. This article explores why you should switch now. We will analyze the core benefits of toroidal designs.

The Limitations of Traditional Inductors

Standard drum core inductors serve many basic purposes. However, they possess several inherent physical flaws. First, they radiate significant magnetic flux externally. This leakage often interferes with nearby sensitive components. Consequently, your circuit might suffer from unwanted noise. Furthermore, traditional through-hole parts slow down automated assembly. You need a more efficient, modern solution. SMD Toroidal Inductor Coils solve these legacy problems effectively. They provide a cleaner and faster manufacturing path.

Three Powerful Reasons to Upgrade Your Design

1. Superior EMI Shielding and Magnetic Containment

The toroidal shape is mathematically brilliant for magnetism. Specifically, the magnetic field stays inside the ring. This “self-shielding” property is a major advantage. It eliminates the need for extra shielding covers. Consequently, you save money on additional PCB materials. Low EMI surface mount toroidal inductors protect your signal. Your devices will meet strict global compliance standards.

2. High Efficiency in a Compact Footprint

Toroidal coils offer very low DC resistance (DCR). Therefore, they generate much less heat during operation. This efficiency is vital for battery-powered mobile devices. Furthermore, the SMD design saves valuable board space. You can place components closer together without risk. Consequently, your final product becomes smaller and lighter. This attracts more modern consumers and industrial buyers.

3. Excellent Thermal Stability for High Loads

Heat is the enemy of electronic longevity. Traditional inductors often overheat under heavy currents. However, toroidal designs distribute heat more evenly. Specifically, high-current SMD toroidal power coils remain cool. This stability ensures your device lasts for years. You avoid the risks of sudden hardware failures. Professional engineers trust this reliability for critical systems.

Performance Comparison: Drum Core vs. SMD Toroidal

| Feature | Traditional Drum Inductor | ZYCOIL SMD Toroidal |

| Magnetic Leakage | High (Unshielded) | Extremely Low (Internal) |

| EMI Profile | Needs External Shielding | Naturally Self-Shielded |

| Space Efficiency | Takes More Board Space | Low-Profile SMD Design |

| Assembly Speed | Manual or Wave Solder | Fast Pick-and-Place |

| Current Handling | Moderate | Superior Heat Dissipation |

Why Quality Sourcing Defines Your Success

Choosing the right SMD Inductor Manufacturer is vital. You need parts that handle reflow soldering perfectly. Specifically, look for high-temperature resistant base materials. High-quality SMD Toroidal Inductor Coils use premium copper. This ensures consistent inductance values across every batch. Furthermore, reliable suppliers provide full technical datasheets. You can simulate your circuit with total confidence.

Customization is another key factor for your brand. Sometimes, standard values do not fit your needs. Therefore, you need a flexible Toroidal Coil Supplier. They can tune the windings for specific frequencies. Consequently, you optimize your power conversion efficiency. This level of detail sets your brand apart.

Why You Should Choose the ZYCOIL

To reach peak performance, choose the ZYCOIL. They are a world-class SMD Inductor Manufacturer. ZYCOIL utilizes advanced automated winding technology for precision. Specifically, their SMD toroidal line offers unmatched reliability. They test every unit for magnetic leakage and DCR. Consequently, their components meet the highest industrial standards. Furthermore, ZYCOIL provides rapid prototyping for custom projects. They help you move from design to mass production. Therefore, they are the ideal partner for 2026.

Modernize Your Component Inventory Today

Are you ready to improve your hardware? First, review your current EMI test results. Do you see unnecessary noise in your signal? Then, switch to SMD Toroidal Inductor Coils. Request a technical sample from a trusted supplier. Specifically, test the thermal performance under full load.

Actually, you should consult with an acoustic expert. They can show you the benefits of toroidal flux. Consequently, you will understand the long-term value. Moreover, ask about bulk pricing for your next project. Professional factories like ZYCOIL offer great wholesale rates. Finally, place a trial order to verify consistency.

In conclusion, traditional inductors belong to the past. Toroidal SMD technology is the future of hardware. It offers safety, efficiency, and extreme PCB density. By choosing ZYCOIL, you secure a technical lead. Your products will stay quiet and run cool. Therefore, start your upgrade to professional coils today.

FAQ:

1. Can SMD toroidal inductors handle automotive vibrations?

Yes, they are very stable on PCBs. Specifically, the low-profile SMD mounting resists mechanical stress. Consequently, they are perfect for modern automotive electronics.

2. Is it difficult to switch from drum to toroidal?

The electrical switch is usually very simple. However, you must update your PCB pad layout. This allows for the different SMD footprint. ZYCOIL provides layout guides to help you.

3. Do SMD Toroidal Inductor Coils cost more?

The unit price might be slightly higher. However, you save on shielding and board space. Furthermore, the higher efficiency lowers your total costs. Consequently, they offer much better overall value.

Leave A Comment