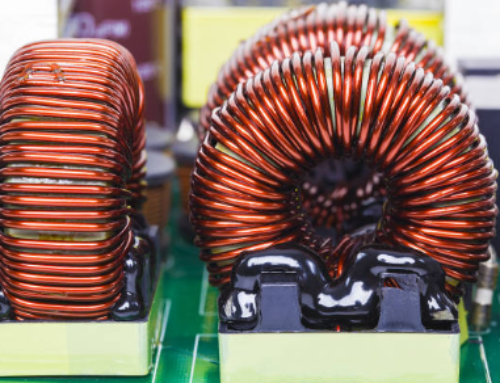

Copper air core inductor coils are among the most reliable components used in high-frequency electronics, providing superior performance in various applications. Their distinct characteristics, such as low resistance and excellent electromagnetic properties, make them indispensable for industries that require precise and high-quality inductance. In this article, we’ll explore why copper air core inductor coils are ideal for high-frequency electronics manufacturing, their key benefits, and how purchasing them wholesale can enhance your product offerings.

What Are Copper Air Core Inductor Coils?

Before diving into the advantages, it’s important to understand what copper air core inductor coils are and how they differ from other types of inductors.

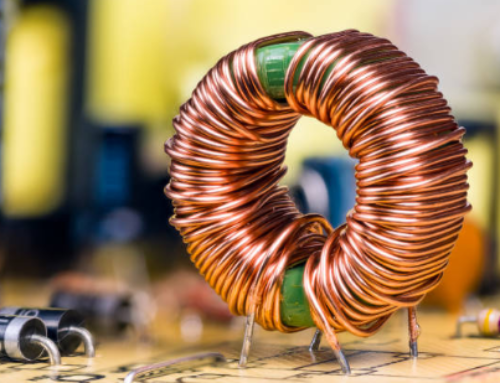

Copper air core inductors are coils made from copper wire wound around a core without any magnetic material (like ferrite or iron). The term “air core” refers to the lack of a solid magnetic core, which sets them apart from traditional inductors that rely on magnetic cores to enhance inductance. Instead, air core inductors utilize the surrounding air to provide inductive properties.

These coils excel in high-frequency applications by eliminating core saturation, thereby maintaining stable performance under demanding conditions.

Why Are Copper Air Core Inductor Coils Ideal for High-Frequency Electronics Manufacturing?

Superior Performance at High Frequencies

Copper air core inductors excel in high-frequency applications due to their low loss and the absence of magnetic saturation. Unlike iron-core inductors, which can saturate at higher frequencies and cause a decrease in inductance, air core inductors maintain their efficiency and performance at elevated frequencies. This makes them ideal for RF (Radio Frequency) circuits, wireless communication, and other high-frequency devices.

In high-frequency electronics, such as oscillators, amplifiers, and filters, precise control of inductance is crucial. The copper air core inductor delivers this with minimal interference, ensuring stable performance even in demanding environments.

Reduced Core Loss and Improved Efficiency

One of the main advantages of ZYCOIL copper air core inductor coils is their ability to minimize core losses. Magnetic core inductors, especially at higher frequencies, can experience eddy current and hysteresis losses due to the magnetic material in the core. Since air core inductors don’t have a magnetic core, they don’t experience these losses, resulting in higher efficiency and less heat generation.

This is particularly important in high-frequency electronics where maintaining efficiency is critical. The absence of a magnetic core also means less signal distortion, which is essential for applications such as signal processing and telecommunications.

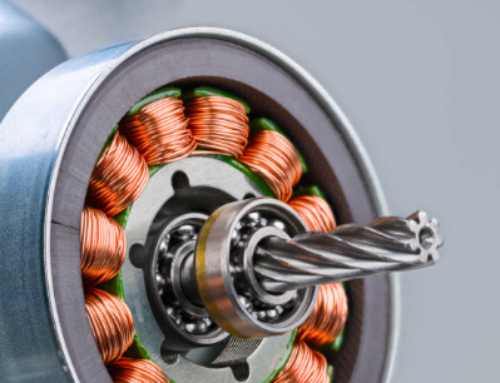

Lightweight and Compact Design

Copper air core inductors are typically lighter and more compact than their iron-core counterparts, making them ideal for space-constrained applications. Whether used in automotive electronics, consumer gadgets, or medical devices, the air core design allows for easier integration into tight spaces without compromising performance.

Their lightweight nature also makes them ideal for portable high-frequency devices, where reducing weight and size is a priority. This can lead to more efficient designs and lower overall manufacturing costs.

Customizable for Specific Applications

Another benefit of copper air core inductors is their versatility and ability to be customized for specific applications. By adjusting the number of windings, wire gauge, and the coil geometry, manufacturers can tailor the inductance to meet the needs of various projects.

This customization serves high-frequency electronics especially well where precise tuning proves critical. Whether optimizing a high-power amplifier, radio transmitter, or filter, copper air core inductors adapt to provide exactly the performance necessary for optimal operation.

The Advantages of Purchasing Copper Air Core Inductor Coil Wholesale

Cost Efficiency in Bulk Purchasing

Buying copper air core inductor coil wholesale offers significant cost savings. When purchasing in bulk, manufacturers can reduce the cost per unit, which is especially advantageous for businesses producing high volumes of electronics.

Lower component costs allow for more affordable pricing in the final product, making your devices more competitive in the market. Wholesale pricing also enables manufacturers to pass on savings to customers while maintaining high-quality standards.

Streamlined Supply Chain and Increased Availability

When purchasing from a reliable wholesale copper air core inductor coil supplier, businesses benefit from more efficient supply chains and consistent product availability. Bulk purchasing ensures that you always have the components needed for production, reducing lead times and preventing delays.

In a fast-paced manufacturing environment, having a steady and predictable supply of high-quality inductors ensures that you can meet customer demand without interruption, which is essential for keeping production on schedule.

High-Quality, Consistent Performance

A reputable wholesale supplier ensures that the copper air core inductors meet strict quality standards, providing you with consistent and reliable performance. These suppliers often test their products thoroughly, ensuring they meet the specific needs of high-frequency applications. By sourcing from a trusted supplier, you can ensure that your products perform optimally, reducing the risk of defects or malfunctions in your end devices.

Conclusion

Copper air core inductor coils are a key component in high-frequency electronics, offering unmatched performance, efficiency, and customization options. Their ability to maintain stable inductance at high frequencies, coupled with their low loss and compact design, makes them an ideal choice for a wide range of applications, from telecommunications to RF circuits.

When you choose to purchase copper air core inductor coil wholesale, you not only gain cost efficiency but also ensure a reliable and steady supply of high-quality components, ultimately improving the performance and reliability of your electronics products. Whether you’re designing consumer electronics, automotive systems, or medical devices, copper air core inductors will help you deliver superior products that meet the high expectations of today’s tech-savvy consumers.

FAQ

1. Why are copper air core inductor coils better than iron core inductors for high-frequency applications?

Copper air core inductors do not suffer from magnetic saturation at high frequencies, unlike iron-core inductors. This allows them to maintain stable inductance and efficiency in high-frequency applications.

2. Can copper air core inductors be customized for different applications?

Yes, copper air core inductors can be customized in terms of winding number, wire gauge, and coil geometry to meet the specific needs of various applications.

3. How do I benefit from purchasing copper air core inductor coils wholesale?

Purchasing copper air core inductors wholesale allows you to reduce costs, streamline your supply chain, and ensure consistent, high-quality components for your high-frequency electronics products.

Leave A Comment